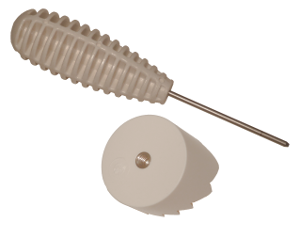

Insert Molding

Insert molding is a process in which a prefabricated part is loaded into a mold for the plastic part to form around. The result is a stronger bond than can be attained through most other methods. Inserts can be made of any material capable of withstanding the plastic injection molding process.

There are a variety of potential benefits to insert molding that can make it an ideal choice for certain parts. Sometimes you need a great deal more strength and durability at a particular point on a part, maybe you require threaded fasteners that lock in more securely than plastic threads, or perhaps your part is a piece of an electronic assembly and requires a conductive path. Often times, assembly by hand can be simplified or avoided altogether by taking advantage of insert molding, yielding a more robust assembly at a lower cost.

Pilgrim Innovative Plastics has been offering insert molding to our customers for years. We have experience with a wide variety of different materials and techniques. Whether you're considering insert molding in the design of a new product or the revision of an existing one, we'll help you to understand the potential benefits as well as the drawbacks so you can make an informed decision. And when you've made that decision, we'll help perfect the design and develop a reliable process for manufacturing.